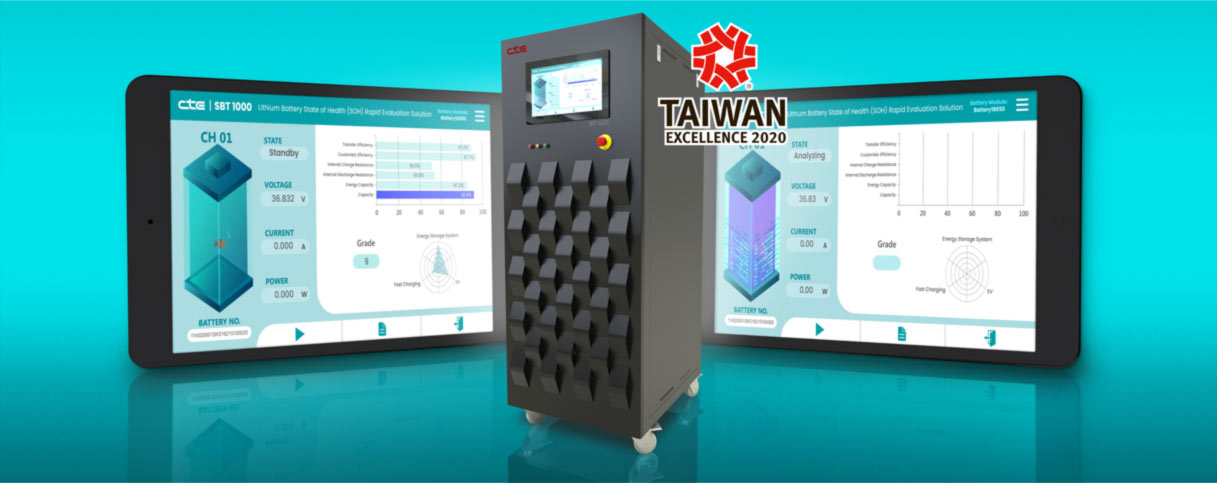

SBT 1000 Series : Lithium Battery State of Health Rapid Evaluation Solution

「Lithium Battery State of Health (SOH) Rapid Evaluation Solution」

Lithium Battery State of Health (SOH) Rapid Evaluation Solution is a user-friendly platform.

It aims to find out the SOH of new/ used batteries and estimate their remaining life,

and the data can be used as references for determining their future applications.

Suitable for the following industries

- EV battery manufacturers:

To sort batteries into groups according to their performances,

or to evaluate retired batteries’ state of health/ remaining life.

- End product provider:

To ensure battery quality during incoming quality control and

get recommended configuration of battery module composition.

- Retired EV battery recycling companies:

To evaluate retired batteries’ state of health.

- Retired EV battery repurposing companies:

To understand the state of health of all reused battery cells,

so the performances of 2nd life application can be secured.

Benefits

- Customization:

According to clients’ requests,

CTE is capable of modifying the weighting of each battery performance indicator,

so the results of SOH evaluation will fit the requirements of applications better.

- Rapid Test:

As long as the aging model and SOC distribute model are built, battery SOH can be evaluated within 60 seconds, which significantly reduces inspection time spent on used EV battery examination.

- High Precision:

Initially, the precision of all battery performance indicators is up to 92%.

By continuously updating database and optimizing SOH model, the precision would improve accordingly.

- Mobile Operation:

The SOH Evaluation test can be executed through mobile devices,

such as mobile phones and tablets, which significantly enhances user experiences.

| Model | SBT 1000 Series |

| AC Power | Customized According To Client Needs |

Loading RangeCharge Discharge | 60V and less 200Ah and less |

| Test Time/ per Battery | <60s |

| Daily Capacity*1 | 720 pcs/CH |

| Modeling Time | 12~25 Days |

| Max. Charge/ Discharge Spec | Depend on Spec |

VoltageAccuracy Resolution | ±0.02% F.S. Depend on Spec |

CurrentAccuracy Resolution | ±0.02% F.S. Depend on Spec |

Cell Voltage Measurement*2Max Voltage Accuracy Resolution | 8V ±0.02% F.S. (±1.6mV) 1mV |

| Ambient | 23°C±2°C; 20~90 HR |

| Communication Interface | Ethernet |

| Accessory | Barcode Scanner、 Barcode Printer |

*1 Calculated with 60 seconds used for testing, 60 seconds for battery replacement, and 24 hours a day

*2 Optional

| Model | Voltage(V) | Current (A) |

| SBT 1000 5V/5A | 5 | 5 |

| SBT 1000 5V/10A | 5 | 10 |

| SBT 1000 30V/50A | 30 | 50 |

| SBT 1000 30V/100A | 30 | 100 |

| SBT 1000 30V/150A | 30 | 150 |

| SBT 1000 30V/200A | 30 | 200 |

| SBT 1000 60V/50A | 60 | 50 |

| SBT 1000 60V/100A | 60 | 100 |

| SBT 1000 60V/150A | 60 | 150 |

| SBT 1000 60V/200A | 60 | 200 |

Application-based SOH Model Development

The formula of the battery has a critical impact on its performances.

Thus, to achieve highly precious SOH evaluation and successful EV battery repurposing,

SOH model should be modified according to battery formula. Moreover,

the accuracy of the model also depends on the number of golden samples (around 5~50)

and time spent on model development (around 1~6 months). In general,

CTE SOH evaluation model reaches a precision of 92% when it is initially built.

Rapid Test in 60 Seconds

Applying high power, rapid data acquisition,

and signal transient response analysis techniques into SOH model development,

it takes merely 60 seconds to evaluate battery SOH and reminding life.

Comprehensive Evaluation Results

The preliminary results of SOH evaluation consist of multiple battery performance indicators.

However, based on different end applications,

CTE will adjust the weighting of each indicator and then generate a comprehensive and brief evaluation result to meet specific performance requirements for the applications.

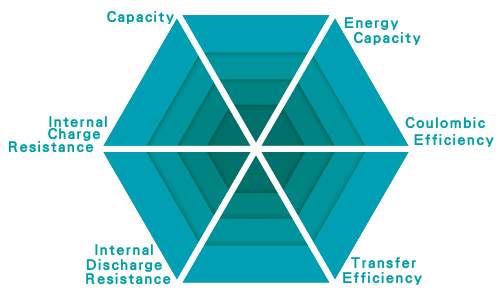

Performance Indicators Used for SOH Evaluation

Quality Assurance

The solution is capable of rapidly and precisely evaluating the performances of numerous batteries.

Also, the reports will be generated automatically,

which significantly increase the working efficiency and decrease workers’ burden in QA department.

Used Batteries Repurposing

The solution is capable of rapidly determining the residual values of used batteries in different 2nd life applications,

which significantly reduce time and cost used for testing and analysis.

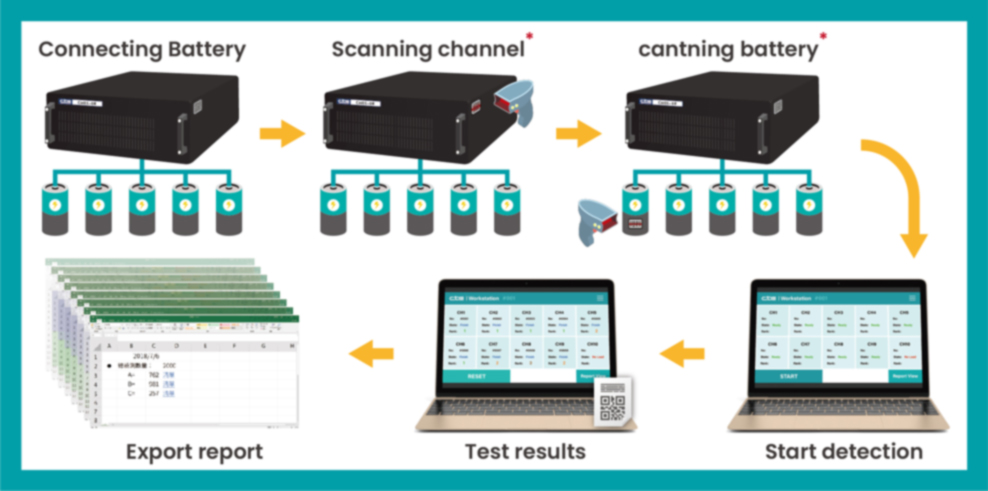

Use Scenario

Barcode Scanner

Barcode Printer