MCE S Series : Eco Series: Lead-acid Battery Formation Equipment

Intro:

MCE is suitable for the formation process required in the production of lead-acid battery. It introduces the discharged energy recycling feature that allows as much as 97% of the electrical energy produced during discharge to be recycled and then supply the energy needed for the charge process, even returned to the grid to provide electricity for other utilities within the factory site. This design greatly reduces the battery production cost and the energy recovery can effectively reduce the temperature rise in the plant, improving the comfort for the operators on-site. To optimize energy use, smart energy management system can be added to monitor the real-time production information at the factory site and obtain important notification and the best scheduling recommendations.

- Support DC-DC and DC-AC energy recovery, with an efficiency up to 97%

- When the system is at full load, power factor>99%

- System load of more than 30%, the total harmonic distortion (THD) <3%

| Model | MCE S Series |

| AC Power | Customized According To Client Needs |

Loading RangeCharge Discharge | 100~300V 100~300V |

Constant VoltageMaximum Resolusion Accuracy | 300V 0.1V ± 0.5% F.S. |

Constant CurrentMaximum Resolusion Accuracy | Depend on Spec* Depend on Spec ± 0.5% F.S. |

| Data Recording Time | 1s |

| Communication Interface | CANBus |

| Ambient | 23°C±2°C; 20~90 HR |

| Optional Features | Smart Energy Management System |

| Accessory | Auxiliary Voltage, Auxiliary Temperature |

*Accept customized request

| Model | Voltage(V) | Current (A) |

| MCE S 300V/0304A | 300 | +3/-4 |

| MCE S 300V/0507A | 300 | +5/-7 |

| MCE S 300V/0608A | 300 | +6/-8 |

| MCE S 300V/1014A | 300 | +10/-14 |

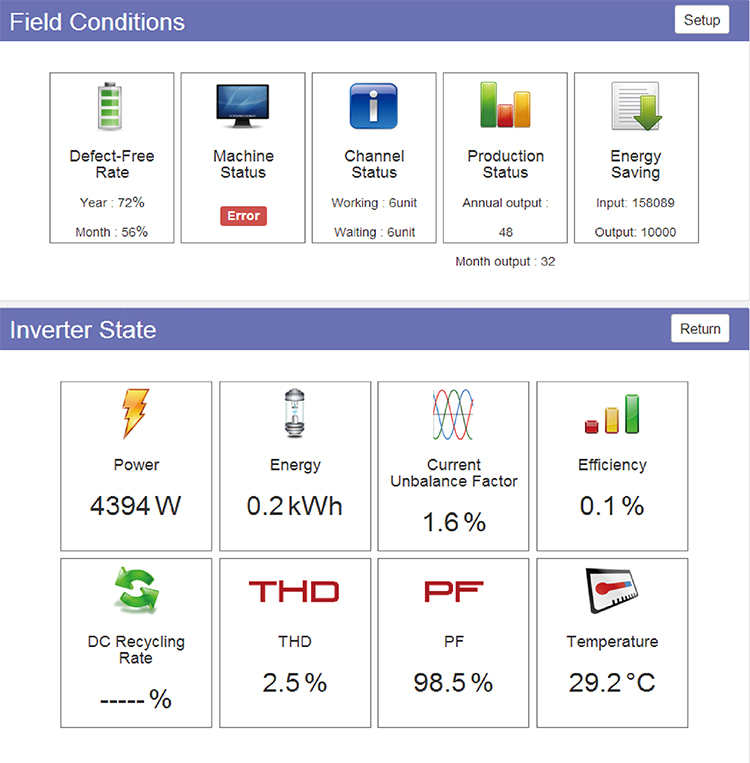

Smart Energy Management System

To optimize energy consumption in a battery factory, 4 major smart energy management features are offered:

- User-centric Dashboard with Remote Monitoring: Present the plant producing information visually, including producing capacity, capacity utilizing rate, energy utilization, etc., and allow users to access to the real-time information through various kind of devices (e.g. smartphone, laptop, etc.)

- Event Notification: Send the event notification automatically to assist facility managers in handling unexpected issues.

- Smart Scheduling: According to the production requirements, suggest the optimal producing schedule to optimize electricity consumption and expenses.

- KPI Management: Monitor all kinds of indicators, compare them with pre-defined KPIs, and then suggest proper corrective actions.

Auxiliary Voltage/ Auxiliary Temperature

Auxiliary voltage and auxiliary temperature are for collecting the voltage and temperature data of a single cell in the battery pack. Collected data can be used as step cutoff conditions while running the battery test, improving the flexibility of the production line and laboratory.

| Model | Auxiliary Voltage ES-100B |

| Channels | 24 |

| Measurement Range | ±64V,±32V,±8V |

| Measurement Resolution | 16 bit |

| Accuracy | 0.02% F.S. |

| Data Recording Time | 100ms (24CH) |

| Model | Auxiliary Temperature ET-100B |

| Channels | 24 |

| Measurement Range* | -50°C~125°C |

| Measurement Resolution | 0.1°C |

| Accuracy | ±1°C (-40°C~90°C) |

| Temperature Sensor | Thermistor |

| Supported Type | 103JT |

| Model | Auxiliary Temperature ET-100C | |||

| Channels | 16CH | 8CH | 8CH | 16CH |

| Scanning Speed | 4CH/s (16CH/4s) | 4CH/s (16CH/4s) | 4CH/s (16CH/4s) | 4CH/s (16CH/4s) |

| Accuracy | ±1°C | ±1°C | ±1°C | ±1°C |

| Resolution | 0.1°C | 0.1°C | 0.1°C | 0.1°C |

| Temperature Sensor | Thermocouple | RTD | Thermistor | Diode |

| Supported Type | Type J, K, E, N, R, S, T, B | PT-10, PT-50, PT-100, PT-200, PT-500, PT-1000, NI-120 | 44004 2.252kΩ, 44005 3kΩ, 44007 5kΩ,44006 10kΩ, 44008 30kΩ | 3904 |

| Measurement Range* | -265~800°C | -200~800°C | -40~150°C | -60~130°C |

*Depend on chosen thermal sensors